My town installed two red light cameras and a speed camera in a 1/2 mile stretch into my neighborhood. They lowered the speed limit too. The week they put up the speed camera I got three tickets for going 42mph and 43mph in a 30mph zone. That made me all warm and toasty inside.

So I thought I'd play with technology to spoil the photos of license plates and share the fun with the world.

Can't jam the radar but I could theoretically make it harder to get a photo of my plate. They want to have really clean photos to stand up in court.

OK - so this is totally for fun and i'm not advocating anyone to break any laws or even bend them.

Whatever you do is totally up to you, I bear no responsibility. If this is illegal where you live, I encourage you not to try it. This is a playground for technology and not anything else. Reading further in this blog is acceptance of the fact we are all responsible for our own actions.

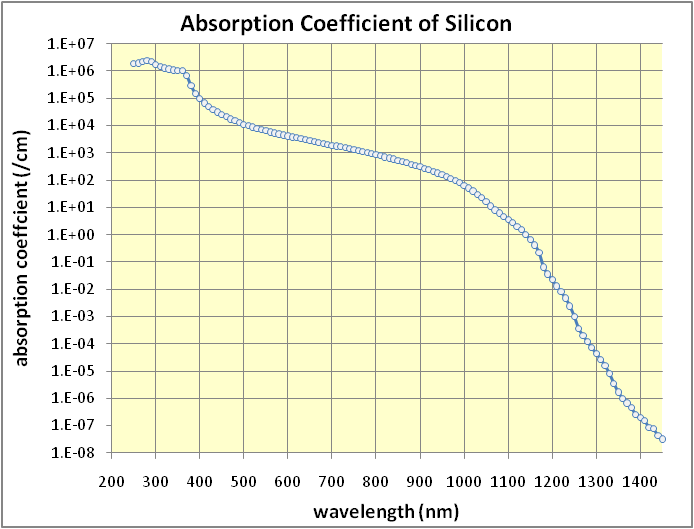

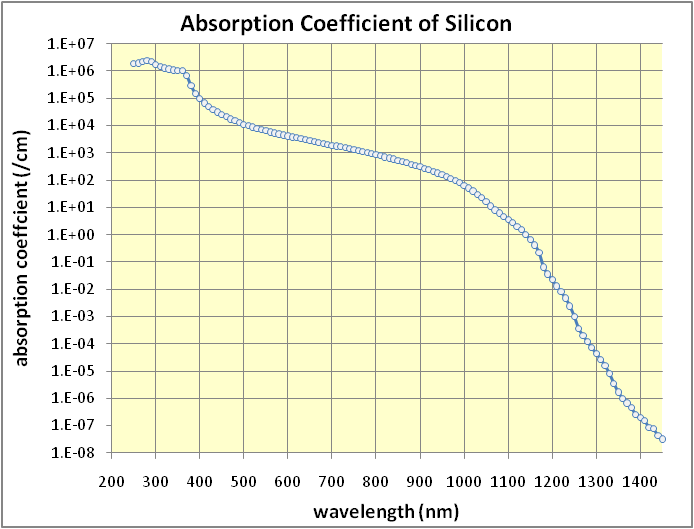

I used to build IR cameras for a living, so I know that all digital cameras are sensitive to

near IR radiation. IR LEDs transmit on wavelengths from 850nm to 1100nm. These are what are used

for IR remotes, etc. Invisible to the eye but visible to silicon digital camera sensors.

Visible light is is 390-750nm. Silicon is used as sensors, and silicon absorbs these wavelengths.

Some filters can be applied to cameras to filter out this wavelength, to improve the

sensitivity of the camera to visible. However sharp filters are almost physically impossible

and very expensive, they require many precisely controlled layers of deposition.

These are also used as invisible illuminators for security cameras, so we know cameras see them.

First I will leave them illuminated all the time, rather than try to catch the flash with a photocell some other nonsense. That is how photographer's flash extenders work, they sense the flash and make another flash fast enough that the shutter is still open, but the sensor is a lot closer and things are much more controlled than the outside environment. Speed cameras must have a pretty fast shutter speed (I calculated this below) too. The reaction time would be short, the flash hard to detect.

There are some phone apps to warn you of these cameras, like this one.

Radardroid Lite

Tried them and they are OK, but it didn't have the same "stickin' it to the man" appeal.

Since IR is invisible, this should be legal. I can't cover the plate, license plate covers are illegal in my state. The IR LEDs must be on the edge of the plate, close enough that some of the numbers can't be photographed due to the "bloom". Just a little glare to make it hard to read and the ticket will be blocked.

I had seen that myth busters tried something like this with visible LEDs and claimed it was busted. But had it worked they wouldn't be able to show it for legal reasons. I'll try IR LEDs, and I'm going

to amp it up with a bunch of lights. The glare will be huge I hope. Daytime light may be too strong, but

what the heck I'll try it anyway. I'm a bit unsure that the lights will be bright enough and this may all be a boondoggle.

One issue will be heat. I want to run the diodes at as high a current as possible. I considered flashing

them at a high rate of speed to cool, but that might miss the exposure all together and the average current

wouldn't be any higher. So I might as well run them off DC to maximze intensity.

There is a possibility that flashing at a high rate might be better to throw off the exposure control

of the camera. However I don't want to risk the lights being off during the time the photo is

taken, so the flashing will have to be fast. I considered flashing them in banks, but that wouldn't

have the effect of messing up exposure control. I think an all on - all off flash would be most disruptive

to photography. I will have to experiment with what works best.

Speed cameras must have long focal length lenses and short exposure times to get sharp photos

of moving cars from far away. That's why they need a flash, they need all the light they can get.

I'm guessing they need exposure times of 1/250 to 1/1000 to capture the moving car.

An electric flash is a very fast burst of light (1/1000 of a second or less, sometimes much less)

Flashing the LEDs at 1kHz would mean that 50% of the time I'd miss being on when the

photo was taken. IR LEDs are designed to modulate at 30-40kHz for remote control.

So modulating at >5KHz will keep the LEDs on for the photo time and will easily be

in the response time of the LEDs.

So I bought 40 IR LED's from Digikey of various wavelengths. I sorted for the highest

power with reasonable field of view, and of course, low cost!!

I already had 10 IR SFH415 U diodes from the IR sleeper and TV bgone projects.

I also bought these others from digikey, all were less than 50 cents apiece.

I wanted a mix of wavelengths but i especially wanted the 850nm ones, because they

will be closer to visible and will put more energy into the camera. Maybe I should

have bought all 850nm, but I thought a mix for experimented would be best to start.

| 1 | 10 | 67-1001-ND | DIODE IR EMITTER 5MM IR CLR LENS | | 0 | 0.48500 | $4.85 |

| 2 | 10 | 475-2871-ND | EMITTER IR 850NM 5MM RADIAL | | 0 | 0.48400 | $4.84 |

| 3 | 10 | 475-1458-ND | EMITTER IR GAAS 950NM 5MM RADIAL | | 0 | 0.31300 | $3.1 |

Links

http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=475-1458-ND

http://search.digikey.com/scripts/DkSearch/dksus.dll?Cat=524328&k=67-1001-ND

http://search.digikey.com/scripts/DkSearch/dksus.dll?WT.z_header=search_go&lang=en&site=us&keywords=475-2871-ND&x=9&y=15

http://search.digikey.com/scripts/DkSearch/dksus.dll?WT.z_header=search_go&lang=en&site=us&keywords=475-1458-ND&x=9&y=14

As you can see, they didn't break the bank! So far I've spend <$20. The traffic tickets were $40 each.

Here is a sample of what they do to a digital camera when illuminated!

I can't show you what they look like to my eye, but they look dark and off.

I'm going to experiment with illumination, photos and placement when the parts come.

Got a license plate frame, plan is to drill it out and insert the LEDs. Got black to

make them less obvious. Got one that had a wide border along the bottom that will

be close to the numbers. This one has a cheezy "carbon fiber look" that has a

shiny woven look that will disguise the LEDs a little better. It is thick plastic and

hopefully will drill. Here is a photo with it on an old license plate

Pilot Automotive WL-714-CF Carbon Fiber Look Car License Plate Frame

http://www.amazon.com/gp/product/B002VKO60C/ref=as_li_qf_sp_asin_il_tl?ie=UTF8&tag=workingsilico-20&linkCode=as2&camp=1789&creative=9325&creativeASIN=B002VKO60C

This was the results of my initial comparisons between the three LED types

IR LED wavelength comment brightness

OED-EL-1L2 950 clear lens, high view angle Highest

SFH 4556 850 glows dull red to the eye Medium

SFH 415 U 950 dark and innocuous looking Medium

Generally, the clear LED was brightest to the digital camera, and the 850nm diode

which should have had a wavelength advantage, wasn't appreciably brighter.

Worse yet, it had some visible wavelength dull red glow. Not bright, but

it would be visible in the dark and raise suspicion. Too bad the clear LEDs are

a little more obvious but seem to be the best.

In this photo the LEDs are in order left to right, SFH 4556, SFH 415 U, OED-EL-1L2, SFH 415 U.

You can see the OED-EL-1L2 is the brightest (third from left). The 850nm diode has no

particular brightness advantage over the 950, which surprised me since it should have several

times the absorption by the camera. It's visible glow is probably going to kill the use of this one.

OK, for the OED-EL-1L2, the peak current is 1A, but the power dissapation is only 150mW

and the DC current allowed is 100mA. The forward voltage is 1.2 to 1.6V

http://www.lumex.com/specs/OED-EL-1L2.pdf

That means that I want to shoot for 150mW to put the LEDs at their max light output.

100mA DC times 1.2-1.6V Vforward = 120mW to 160mW. So I have to keep the average

current to 100mA. My prototype will power the LEDs from 5V Arduino output but later

I may make a 12V simple circuit to do the oscillation. 5V/100mA is 50 ohms. But since

I'm flashing at 50% duty cycle, I will need 25 ohm resistor in series. The above photo was

takin with 100ohms, so I will be twice as bright as that.

Obviously the Arduino can flash an LED at that kind of current. The TV bgone uses a 2n3904

bipolar to switch the current, without any series resistor. I also have a pile of 2n7000 mosfets

that will save me some resistors. They can take 350mA. This was the tv bgone circuit. As

you can see it needed two stages to fan out the current drive. the 2N7000 won't need that

as the gate draws no current. Everyone should buy a bag of these, for 0.17 for 100.

To avoid a series resistor, I could drive the LED with a low duty cycle high current pulse.

The 2N7000 has a Rds(on) of about 2 ohms at 0.5A.

http://www.st.com/internet/com/TECHNICAL_RESOURCES/TECHNICAL_LITERATURE/DATASHEET/CD00005134.pdf

The LEDs could handle 1 amp peak (remember from above). 5V - 1.5V (Vforward) = 3.5V across the transistor. 3.5V/2 ohms = 1.75A. Too high for the LED without any series resistance. But if I put two LEDs in parallel, I will split that current and be at 0.875A per LED. This is not a perfect solution because the

LEDs may have slightly different forward voltages, and will not share the current equally. But best I can do.

Now I have to keep the LEDs from dissipating more than 150mW on average.

0.875A * 1.5V = 1.31 W peak. 150mW/1.31W =11.5% duty cycle.

SoI could flash LEDs at 10kHz, with 11.5% duty cycle, two LEDs per 2N7000 transistor, no series resistors. 5V supply.

To save components, I could bring the duty cycle up to 50%, and load on more LEDs in parallel.

I could put 10 LEDs on at 50% duty cycle, 0.50 * 1.75A * 1.5V / 10 = 131mW per LED.

I'm in trouble on the 2N7000s. they only want 1.4A peak current, and I'm doing 1.75A.

Thought I'd run it anyway, if I blow one they are cheap. However it gets scary hot and the

LEDs don't at all. I think I will switch out the 2N7000 with a FQP50N06L monster.

These cost a over a buck a piece but they are 50A rated.

Problem is they have a really low Rds(on) = 0.2 ohms. So my current calculations are

out the window and i need to introduce a 2 ohm resistor. Arrgh.

OK. Rethink time. Is flashing really better than DC? Time to experiment because flashing

is going to take many more components. DC will take a couple resistors, while flashing will

require an oscillator, switching transistor, etc.

I set up an experiment flashed, side by side with DC. The flashed had 50% duty cycle with

half the series resistance. 100ohms for flashed, 200 ohms for DC. The DC was noticeably

brighter to the camera. OK. DC wins for complexity and effectiveness.

The lower 5 LEDs are the DC, the upper 5 are switched at 10KHz.

I mocked up an array of LEDs and resistors and plugged it into 12V for one last full

scale test before building up the license plate final version, and got a surprise.

While this was on, it started to smell hot. The resistors were getting really warm. Doh! I have 1/2W 100 ohm resistors, so that I put (12V-1.5V)/100ohms=105mA through the LEDs, their max rating. However since I'm running from the 12V auto supply directly, that puts 10.5V * 1.5mA = 1.1W through the resistors. Before I had been running off 5V during tests and the resistors did not get so hot. This simpleton project is becoming more complicated because I'm trying to make a cheap solution.

OK, brain finally started functioning. Many LEDs will be in series with a resistor

to set the current, this will prevent dissipating too much power in the resistor

and generally be more efficient, fewer components, all good.

6 LEDs in series like christmas lights, 6*1.5V=9V. 12-9V=3V across the resistor.

100mA*3V=300mW, which is in spec for the 1/2 watt (500mW) resistors. Might even

be able to squeeze in a 7th LED. 3V/100mA= 30 ohm series resistor.

Tested out strings of 6 LEDs in series with 30 ohms. Gets nice and bright, doesn't get hot, doesn't waste power.

OK, here is the complete circuit drawn up. Strings of 6 LEDs will be used.

I think I can pack the LEDs in and solder them into chains. So the big structure at the bottom will look like two rows of alternating staggered LEDs with no interruption in the middle for the ground.

There will be a tight cluster in the bottom center of the plate, and a smaller cluster at each side which is nice and close to the numbers.

Drilled a hole in the license plate frame as a test (see link above) and it drilled pretty well, nice clean hole.

The challenge is going to be making nice neat regularly spaced holes or the whole thing will look amateur.

I put one of the clear IR LEDs that won the brightness test, but it looks really obvious in the frame. Maybe somebody with a tricked out car might not care, but it really looks like a light, even when it is off. The solid color SFH 415 U look far better and less suspicious. I'm going to have to use those, i'd never have the nerve to put the others on the car. Forget the nice shiny OED-EL-1l2s.

Hard to get a good photo to show what i mean, but here it is...

Obvious Clear LED (shown off, which is how it looks to the eye). I thought the pattern would hide it.

Nearly invisible black IR LED. It is a bump of course and the picture isn't great. But you get the point.

I was planning to use my CNC machine that I've been writing about to drill the holes. Sorry if not everyone who reads these happens to have one. However the CNC machine stage is small enough I'd have to do the job in three passes, and I got impatient with the setup and just did it on the drill press. I clamped a bar to the press stage to make all the holes even distance from the edge of the frame, but freehanded the spacing. I was eager to move this project along and get to some outside trials. I did OK but not great in spacing the holes and kinda goofed on getting the placement of the arrays even on both sides. No harm done but a production version would have to be neater. The plastic license plate frame drilled nicely though, it was a good choice for the project.

Here is a picture of the holes I drilled. I put the LEDs in clusters to make hot spots in the photo, rather than in a whole line around the plate. The thought is that unevenness and tight hot spots will be best to ruin the photo.

Next to glue in the LEDs and wire them up! A note about LEDs since a few non EEs seem to be reading this post. LEDs aren't light bulbs. They have a polarity and must be hooked up the right way or they don't light up. This is how you tell which way to put them in. Note that not ever LED follows the long lead convention, but the flat side is a reliable indicator of polarity.

Here is a shot of the LEDs getting glued into the main phaser bank in the middle. Remember that they are in strings of six, so the pattern of anode and cathode is important to be able to easily solder them into strings. I will show the pattern later. This is about the best I've been able to capture the look of the LEDs in the frame. They are hard to see.

Daisy chained LEDs soldered up to 30 ohm resistors. Glued in the LEDs and bent the leads and soldered them together into chains of six. Make sure to keep the polarity correct in the chains. A little messy but this is a prototype.

Here is the finished main LED array (sorry about the 90 degree photo). Power is off in this photo so you can see how it looks to the eye

OK moment of truth. Did it work?? Eh maybe....

So a lot depends on the lighting. Taking a photo of a moving car and reading the license plate is not easy. A speed camera needs a lot of light, a high speed lens, a short exposure time. So it shouldn't take much to spoil the photo. This photo was taken with indoor lighting and no flash. The picture is very messed up, lots of glare but all in all you can still read the plate if you try. It might not meet the standard of quality to hold up to get you a ticket though. Of course you don't want to mess up the photo just enough to have them wonder what you are up to. You can read my plate here, but eagle eyes will reveal this is just an old expired plate I'm using as a photo model.

This time I used the flash. The IR LEDs are a nice decorative touch, but pretty much useless. However I'm 3 feet away shooting a plate that isn't moving. A real photo won't be this good. Anybody's TV remote in the neighborhood would be probably be totally jammed :-)

I went out on a fairly sunny day and put it on the car. Stylin' huh? All in all I succeeded in making something that is not going to draw any attention under normal circumstances.

Powered it up with a battery charger to start. This later proved to be a slight issue. Can you read the plate? I can. Is it even on?? It was so bright outside I couldn't see the display on my camera. This is a tough test. It was bright and sunny. The car was not moving of course, but I also didn't have a professional camera. if you see below, it might be better than this photo showed because of the power supply I was using.

Here is a closeup like what you get in the mail when you run a camera. Still looks like a FAIL. The LEDs are pretty but noneffective under these lighting conditions. Notice something strange happened, which may have reduced the brightness. The LEDs were powered from a battery charger in this picture, and it has a lousy AC to DC rectifier that is probably flashing the lights at 60Hz. When there is this much light, the camera is taking an exposure shorter than the time it takes to read out the camera's photo array (I told you I used to design IR digital cameras for a living, trust me). As a result the picture changes while it is being taken, and the 60Hz is not integrated and the LEDs appear to be on in different patterns every time you take a photo. That won't happen with the car's DC power, so it might be twice this bright when hooked into the car power. That is why it looks like some of the LEDs are not working. But anyhow there is zero glare.

So here is my conclusion for now. There is hope that this would work when it's dark, rainy, or otherwise non ideal for photo taking. On a sunny day, drive slowly. Or make the LEDs spell out a message like "I love the police". I'm not going to go out and run a camera on purpose, so there is no way to know if this is going to work even on a dark night.

Next.... Ramping it up!

What went wrong? I had the design parameters turned too far for innocuous, stylish and low cost. I need to redo the project and focus on brightness and high power and see if I achieve something that works first.

The clear LEDs were 50% brighter in my early tests, but I chickened out from using them. I went for cheap LEDs and simple circuits. Since then I've seen light up license plate frames for sale so I think the lights could be more obvious without attracting attention.

Some other notes for other ways to do this project...

Later I saw someone driving down the road with this:

So if you wanted you could buy one of these, already has the power connections, and replace the glowing eyes with 850nm high power LEDs. This is not my style, but if it is yours it is an easy way to beat the camera. The 850nm LEDs would glow and look like it did before, and be totally undetectable. Not enough room for all the LEDs I'm using, but could give you a little help.

A little googling found this too. So this could serve as a starting point for a mod, replacing the LEDs with IRLEDs and keeping low profile.

You could also get one of these, and ramp up the power. This alone has 140 LEDs, but I don't know what type so there is no way to know if you could achieve enough brightness.